Back to top

Our Services

We have a cross-functional team, which handles all our tasks including after sales support. We regularly design customer-friendly products by following planned processes. Our service engineers periodically visit the site to prepare effective layouts and obtain a detailed understanding of processing parameters. The operators working with us attend the necessary training to perform service tasks. With their support, we render erection and commissioning solutions of our equipment with the highest care.

Our Team

Our operations are professionally performed by experts, who have excellent academic background and bring remarkably positive outlook to the company. Due to their excellent knowledge of specific technology and rich engineering skills, we can say that we have the best team in the domain. We are supported by highly experienced product designers, trained engineers and technicians, sincere production experts, and dedicated businesses and marketing officials. With the support of all the appointed professionals, we have earned the prominence as a fastest growing entity.

Manufacturing Facilities

A key contributor in our rapid growth and business expansion is our modern infrastructure. Here, we employ modern production techniques to maximise the development that results from these machines that have been installed in all the departments. Our infrastructure spans over a large area and consists of a highly efficient production unit, inspection division and packaging and shipping department.

The handling, cutting, and machining of all the materials available in our setup are done by skilled workers. With the support of a highly skilled fabrication team, we also render turnkey projects.

Quality Assurance

In order to provide the most ethical and unbiased product selection to our valued customers, we periodically evaluate the most recent business trends, but while doing so we never undervalue the significance of ethical codes.

For gaining the complete trust of our every customer, we make sure to offer products that are made from the finest materials. We obtain the finest raw material inventories from a network of certified vendors. On our premises, we follow a strict quality policy, which enables us to carry out the necessary testing and audits up until the shipment of a consignment is made. As a part of quality promises, we also ensure about the right manufacturing statutes and moral business practices.

We have a specialized quality department that inspects products to ensure they meet customer specifications.

Clientele

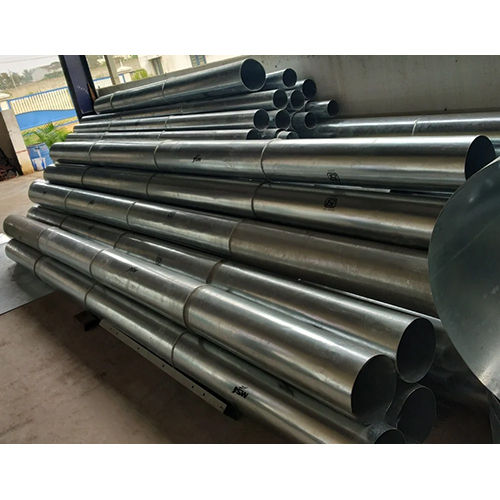

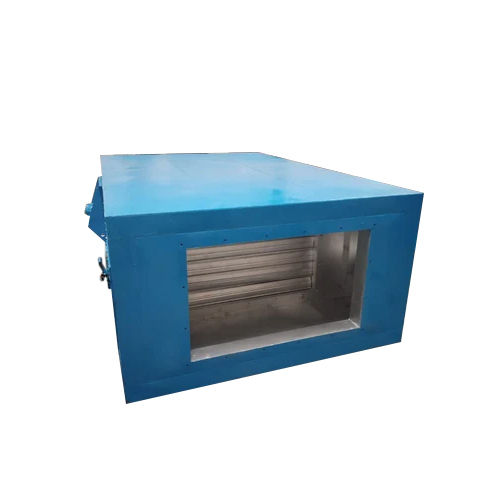

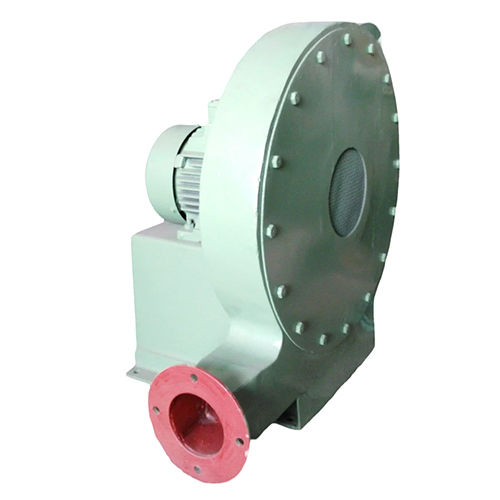

Experienced at manufacturing and supplying reliable Kitchen Exhaust Fan, Plug Ventilation Fan, High Pressure Blower, Paint Booth Blower, Suction Centrifugal Blowers, Round Exhaust Ducts, Duct Pipe, Metal Dust Collector, Heat Exchanger Box, and many other products.

In 1987, Fine Fab India, was started, and since then we have been meeting the varied market needs with our vast product line, which includes High Pressure Blower, Metal Dust Collector, Kitchen Exhaust Fan, Plug Ventilation Fan, Round Exhaust Ducts, Duct Pipe, Heat Exchanger Box, Paint Booth Blower, and Suction Centrifugal Blowers.

With our unique multicultural business policies and client-centric approaches, we are running operations and registering high growth. We have precise engineering knowledge and exceptional technical expertise that get reflected in the supreme quality of our cutting-edge machinery. Our creations are praised for their effective operation, easy installation, longer functional life, and low maintenance.

With our unique multicultural business policies and client-centric approaches, we are running operations and registering high growth. We have precise engineering knowledge and exceptional technical expertise that get reflected in the supreme quality of our cutting-edge machinery. Our creations are praised for their effective operation, easy installation, longer functional life, and low maintenance.

As an

organization, we work with fundamental values that enable us to meet the

market demands for massive and complicated machines. In order to

develop user-friendly and extraordinary modern machinery, we employ

cutting-edge software tools and latest procedures. Our machines come

with the newest tool management software that are the result of the

excellent manufacturing knowledge of the team members. Furthermore, we

consider honesty as the cornerstone of our business practices. By

staying honest in practices, we meet even the complex needs of a large

number of clients around the nation.

We are keen to have excellence. Our mentor, Mr. Rajesh Babu, helps us to go above and beyond to have excellence in all the tasks that we do. His expertise, good business decisions and extensive industrial expertise help us to uphold the best production practices and strict moral standards of ethics. Under his supervision, we also render after sale service including the installation and maintenance of our products.

Application Areas

We are keen to have excellence. Our mentor, Mr. Rajesh Babu, helps us to go above and beyond to have excellence in all the tasks that we do. His expertise, good business decisions and extensive industrial expertise help us to uphold the best production practices and strict moral standards of ethics. Under his supervision, we also render after sale service including the installation and maintenance of our products.

Application Areas

|

|

Our Services

We have a cross-functional team, which handles all our tasks including after sales support. We regularly design customer-friendly products by following planned processes. Our service engineers periodically visit the site to prepare effective layouts and obtain a detailed understanding of processing parameters. The operators working with us attend the necessary training to perform service tasks. With their support, we render erection and commissioning solutions of our equipment with the highest care.

Our Team

Our operations are professionally performed by experts, who have excellent academic background and bring remarkably positive outlook to the company. Due to their excellent knowledge of specific technology and rich engineering skills, we can say that we have the best team in the domain. We are supported by highly experienced product designers, trained engineers and technicians, sincere production experts, and dedicated businesses and marketing officials. With the support of all the appointed professionals, we have earned the prominence as a fastest growing entity.

Manufacturing Facilities

A key contributor in our rapid growth and business expansion is our modern infrastructure. Here, we employ modern production techniques to maximise the development that results from these machines that have been installed in all the departments. Our infrastructure spans over a large area and consists of a highly efficient production unit, inspection division and packaging and shipping department.

The handling, cutting, and machining of all the materials available in our setup are done by skilled workers. With the support of a highly skilled fabrication team, we also render turnkey projects.

Quality Assurance

In order to provide the most ethical and unbiased product selection to our valued customers, we periodically evaluate the most recent business trends, but while doing so we never undervalue the significance of ethical codes.

For gaining the complete trust of our every customer, we make sure to offer products that are made from the finest materials. We obtain the finest raw material inventories from a network of certified vendors. On our premises, we follow a strict quality policy, which enables us to carry out the necessary testing and audits up until the shipment of a consignment is made. As a part of quality promises, we also ensure about the right manufacturing statutes and moral business practices.

We have a specialized quality department that inspects products to ensure they meet customer specifications.

Clientele

|

|

|

FINE FAB INDIA

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

Send Inquiry

Send Inquiry Send SMS

Send SMS Call Me Free

Call Me Free